Combatting Ecommerce Supply Chain Disruptions and Steps You Can Take to Minimize Impact

Brett Regan

Combatting Ecommerce Supply Chain Disruptions and Steps You Can Take to Minimize Impact

Get The Print Version

Tired of scrolling? Download a PDF version for easier offline reading and sharing with coworkers.

A link to download the PDF will arrive in your inbox shortly.

When everything goes right, it’s like a magic trick. A customer goes to the store and finds exactly what they need (and often plenty of brands and options) neatly stacked on shelves.

Or if they order online, they can receive a box on their porch as quickly as one or two days later.

In many places, and especially in first world countries, people have become accustomed to these conveniences. But when the supply chain is disrupted by local events like natural disasters or global events (like pandemics), suddenly the magic seems like it was all smoke and mirrors.

Supply chain disruptions create scary and uncertain times for businesses and consumers alike. They also draw attention to our supply chain dependencies that we are otherwise not aware of when everything is operating like a well-oiled machine.

Sometimes these disruptions are small and localized, and may affect only a few businesses or industries. Other times they are globally felt, especially when the hard hit region is a source of a diverse range of supplies, as with many Asian markets.

The COVID-19 global pandemic has caused a major upheaval in the supply chains of many businesses in the United States and North America.

In a study conducted by the Institute for Supply Management, almost 75% of the 628 businesses surveyed had experienced supply chain disruptions as a result of the COVID-19 outbreak. In this same survey, 57% of respondents said they were facing longer lead times for orders with suppliers in China.

Dr. Bob Novack, Associate Professor of Business Logistics at Penn State explains, “This pandemic is like a natural disaster, but it’s also not. The results of a natural disaster on the supply chain are usually localized and short-lived. In a pandemic it’s global. It’s the rapid increase in demand that a pandemic creates that puts additional strain on suppliers.”

In this article, we’ll look at common causes of disruptions, some of the ways you can prepare for disruptions you are currently facing, and how to create a plan to better manage your supply chain risk management in the future.

What is a Supply Chain Disruption?

A supply chain is a network of people, organizations, and activities that move a product from a supplier to a final customer. A supply chain disruption is any sudden change or crisis—be it local or global—that negatively impacts that process.

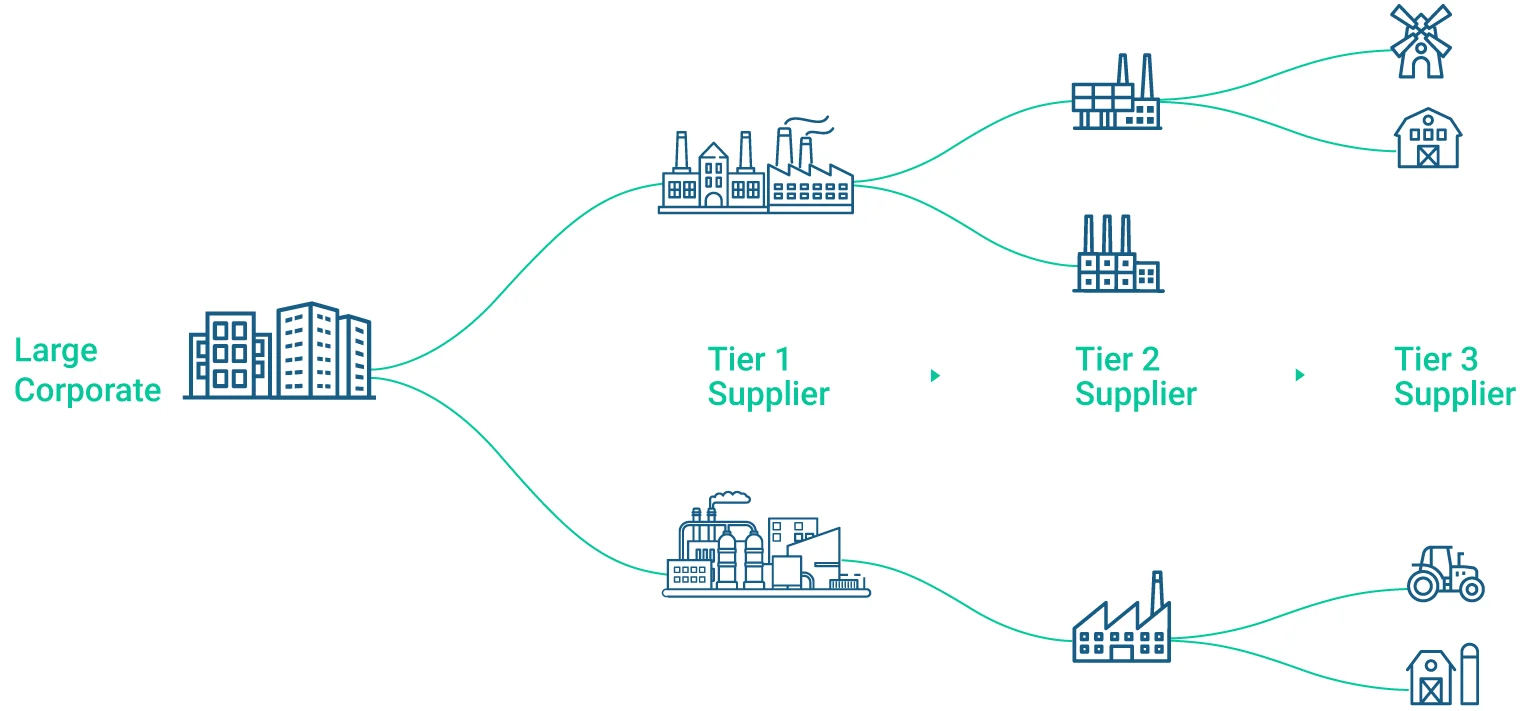

You can think of supply chains as a series of interconnected parts like, well, a chain. In complex manufacturing, you may have also seen different tiers of a supply chain illustrated as a pyramid.

Image from Transper__.

The original equipment manufacturer (OEM) is at the top of the pyramid. Tier 1 suppliers are the last step before the OEM (or sometimes distributors themselves). They are the final step before the OEM which may market and distribute the product to end users.

Tier 2 suppliers produce and supply parts to Tier 1 suppliers. They are usually smaller businesses, but no less important in the supply chain. They must adhere to strict safety and regulatory standards to make sure their products will be accepted by Tier 1 companies.

Tier 3 suppliers are the foundation of the supply chain in that they provide raw materials like metal and plastics from which the other suppliers can construct specific products.

Not all items and industries will have all tiers in the chain. Some supply chains will be much simpler or more complex, but for the vast majority of businesses, they will be a factor in some form for fashion.

This interdependent chain can experience delays and inefficiencies regardless of where the disruption occurs. These effects are compounded when one supplier is the only source for that part of the supply chain or when one area holds most of the options for a particular supply.

As mentioned in the introduction, consumers are rarely aware of all the intricate parts and operations that go into getting them their complex piece of electronics or even a simple item like a roll of toilet paper until they aren’t available.

5 Types of Supply Chain Disruptions

Not all supply chain disruptions are created equal. As Dr. Novack explains, “There are many different types of supply chain disruptions. When you look at a disruption, there are two things you have to look at: 1) what is the probability and 2) what is the severity.” This will vary depending on your supply chain and your industry.

Here are some of the reasons your supply chain might see an impact.

1. Pandemics.

We’ve seen in recent weeks and months how COVID-19, the novel coronavirus outbreak, has impacted global supply chains. The effects of global pandemics or other public health crises can have massive supply chain impacts because of the number of people, regions, and global companies affected which can upend normal operations at every stage of the production line.

2. Natural disasters.

On March 11, 2011 an earthquake struck off the Pacific coast of Japan causing a tsunami which in turn led to a nuclear disaster at the Fukushima Daiichi Nuclear Power Plant. The catastrophe affected many businesses and the global economy, temporarily shuttering those that reportedly produced 22% of the world’s supply of 300-millimeter silicon wafers (a necessary component in semiconductors) along with 60% of certain necessary auto parts.

Natural disasters like this one—or hurricanes, tornados, wildfires, or floods—often draw attention to supply chain dependencies in the affected areas. Even a localized disaster can have far reaching implications in the supply chain depending on where it is.

3. Transportation failures and delays.

Globalization and increased trade has made it more and more common for supply chains to include international suppliers. A result of this is increased business opportunities, but also increased strain on international and domestic transport networks which has led to congestion and delays.

While transportation delays can happen in the best of times, other supply chain disruptions can compound these problems. For example, natural disasters can prevent transportation and trade routes through affected areas. Or in the case of the COVID-19 pandemic, many countries and regions instituting lockdowns to avoid viral spread is making it more difficult for freight carriers to deliver goods by land, sea, or air slowly the movement of even vital products.

4. Product problems.

Quality management goes hand in hand with supply chain management, as issues with products at any stage in the chain can lead to issues and delays in the final product. No business wants to send sub par merchandise to customers or have customers’ shipments delayed because of faulty products, so creating a good quality management system with customers expectations in mind, and communicating that to all suppliers is important.

5. Price fluctuations.

Price changes for suppliers in your chain can also create disruptions as you may have to make a decision on whether or not to switch suppliers, raise your own prices, or see your profits reduced by eating the costs yourself. Price fluctuations can be caused by any number of factors. For example, prices on commodities like crude oil are notoriously volatile and can have a big impact on the financial overhead of a number of manufacturing and transportation factors.

6. Cyber attacks.

Cyber attacks can occur to any business at any time who has not adequately protected themselves. Your supply chain can also inadvertently open you up to attacks. If any link in your chain has lax security protocols, that may be an opportunity for hackers to get access to your data.

This is what occurred in 2014 when superchain Target experienced a major security breach that was originally started though a hack in their HVAC partner though a phishing scheme. The chance of your supply chain being disrupted by cyber attacks or leading you to be attacked yourself, make it very important to have strong communication and relationships with all links in your chain and know where any vulnerabilities may lie.

7 Tactics for Preparing for Supply Chain Disruptions

The following section was contributed by Gayatri Bhaumik on behalf of EasyShip, an all-in-one shipping platform for global ecommerce__.

They say the best offense is a good defense, and that’s certainly true when it comes to managing your supply chains. You probably won’t get much advance notice about disruptions to your supply chain, so it’s a good idea to make sure you plan ahead for any eventuality. Here are a few things to consider while creating a strategy for managing supply chain disruptions.

Create a supply chain emergency plan.

Build up inventory.

Conduct a supply chain vulnerability audit.

Identify backup suppliers.

Diversify supply base.

Partner with a logistics expert.

Adopt risk evaluation tools.

1. Create a supply chain emergency plan.

It’s always good to have a backup plan, especially when it comes to supplies. When creating an emergency plan, you should think about all the different ways you can move goods around and consider setting aside an emergency budget that can be used in case of disruptions.

2. Build up inventory.

Create a stockpile of essential supplies that can see your business through several months of disruption. This might mean having a store of finished goods, components or even raw materials – whatever you might need to maintain your business if your supply chains are temporarily cut off.

3. Conduct a supply chain vulnerability audit.

Take some time to do a risk analysis and see where the weakest links in your supply chains are. This will help you focus on where you need to find alternatives. It can also be helpful to assess potential environmental, social, and political conditions that may impact your supply routes.

4. Identify backup suppliers.

Look at what other suppliers can provide what you need if your current supplier can’t get your goods to you. This will probably mean identifying suppliers in other geographic locations and building a relationship with them so that they can step in when you need them.

5. Diversify supply base.

Like an investment portfolio, a little diversification in suppliers can be a good thing. By setting up your supply chain so that you have suppliers in different places, you can ensure that you’ll always be able to get at least some goods amidst any disruption.

6. Partner with a logistics expert.

Find a fulfillment and supply chain expert that can step in to support you when disruptions happen. They should be able to help you locate alternative courier solutions and help you understand how to deal with disruptions and navigate fees and surcharges.

For example, Easyship integrates directly with BigCommerce and can provide global logistics support through their easy-to-use platform that allows users to show delivery lead time and taxes and duties at checkout, which can go a long way in helping you manage customer expectations during disruptions.

7. Adopt risk evaluation tools.

Use technology to evaluate potential threats to your supply chain. Try AI-enabled mapping and environmental analysis solutions, aggregate apps that provide geopolitical overviews, and systems that can evaluate cyber threats. Even social media can be used as a predictive tool to identify potential shortages and disruptions.

Steps to Take When a A Disruption Has Occurred

Of course the above is great for planning ahead longterm, but what happens if your supply chain is currently disrupted and you’re figuring out how to solve issues and continue to move forward in the short term? In this section, we’ll look at the more on-the-ground, crisis management solutions you can take to solve for evolving supply chain disruption issues.

1. Communicate with customers.

Being transparent with customers is essential to get through these times. If you are upfront about the delays and the reasons for them, your customer base is more likely to be understanding.

Kristina Lopienski, Sr. Content Marketing Manager at ShipBob, recommends: “If you are low on stock, limiting purchase amounts, or have modified shipping speeds, share that on your site or over email early and often.”

And communication shouldn’t stop with customers, Kristina adds: “O__ver communicate, which happen to be rule #1 when working remotely too. Communicate consistently to your customers, to your distribution partners, to your team.”

2. Evaluate all critical components of the supply chain.

Figure out what you absolutely need to continue operating going forward and the origin of their supply. Look to establish alternative suppliers for critical parts and products first.

According to Karl Siebrecht Co-Founder and CEO of FLEXE, a warehousing and fulfillment solutions provider, this evaluation process should encompass not just the businesses in your supply chain, but every aspect of your business:

“When your business is disrupted, it is critical to take a step back and clarify what is most important to optimize for. Is it employee well-being, customer satisfaction (and for which segment), near-term cash flow, or something else? In a crisis, it is likely you’ll have to make some very tough trade offs.

Developing decision-making criteria that can be consistently applied will clarify issue-by-issue decisions. Once you’re on the other side, identify key insights for the next time, because the unfortunate reality is that disruptions happen. So when they do, know your options.”

3. Estimate available inventory.

Generally, you should have a good account of your available inventory at any given time; however, it’s particularly important at times when your supply chain is disrupted. You may want to do a physical inventory and audit of not only what finished products you have available, but also what components and spare parts are available that can keep production running.

4. Assess buyer behaviors.

As quoted by Dr. Novack in the beginning of this article, some supply chain disruptions are also compounded by changes in demand. For example, a global pandemic or far-reaching natural disaster can change what and how consumers are purchasing. Keep track of how changing buying behavior is affecting which of your products customers are seeking. If necessary, considering pivoting your products to match demand.

For example, CBD brand, CBD for Life started offering hand sanitizers as one of their products in response to growing demand.

5. Optimize production and distribution capacity for safety.

The safety of your employees and those of your fulfillment partners is of the utmost importance. Make sure to optimize your production and distribution strategies to make sure your products are being made and delivered in a way that is safe for everyone involved.

For the COVID-19 pandemic, Kristina Lopienski of Shipbob offers the following advice for optimizing safety, which could be tailored in the event of other disruptions and crises:

“Stay up-to-date from trusted sources on COVID-19 from the CDC, the WHO, and local government and health organizations. We have been summarizing everything we have found as quickly as we can on our side__, especially as it pertains to both the receiving and fulfillment of goods across our entire network.

Lastly, err on the side of caution. For those who can work from home, require that. If you have your own fulfillment production teams that are still operating, make sure you’re taking appropriate measures, such as increasing how often you clean and disinfect the entire facilities, require protective gear to all people internally and visitors like carriers, extend sick time, and possibly find ways to give extra financially to those who need help with childcare or health issues.”

6. Identify logistics flexibilities.

Now is the time to be flexible. Identify places where you can afford to decelerate and accept slower delivery and alternative transportation methods. This goes back to the importance of communication: make sure your supply chain relationships are strong and that you’re appreciative of the efforts all your suppliers are putting in to continue to work with you as efficiently as possible.

7. Evaluate cash flow impact.

Some impacts to your bottom line may be inevitable. Run stress tests to see where supply chain disruptions are most likely to have a financial impact, so you can plan accordingly and make adjustments to your overhead as needed.

Conclusion

When your supply chain is operating undisrupted, it’s easy to take it for granted. However, in times of trouble, having a good long-term plan in place (or being able to create a strong crisis management strategy in the moment) is essential.

Supply disruptions are inevitable, but by planning your response carefully, evaluating potential supply chain risks, and diversifying your suppliers, you can help prepare for even the most unprecedented of circumstances.